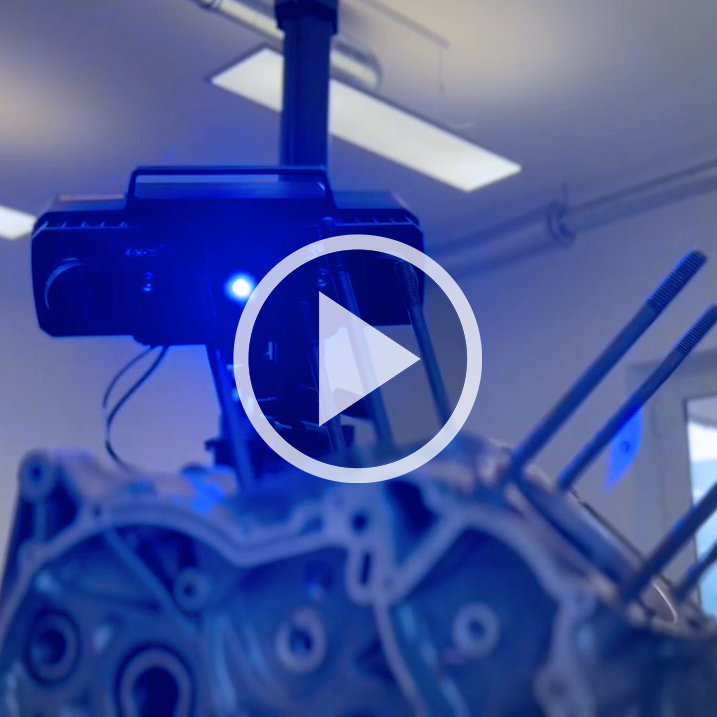

SERVICE PROVIDER FOR OPTICAL

3D SCANNING AND MEASUREMENT TECHNOLOGY

We are your service company in the field of industrial 3D measurement technology. Together with our team and the highly accurate GOM measuring systems from ZEISS, we provide you with precise three-dimensional measurement data and reliable measurement reports for product development and series production.

Why should you choose us?

High know-how in special industries and absolute flexibility. Our way of working is as flexible as our quality control technology. You decide whether you bring your components to us or whether we come to your company with employees and state-of-the-art equipment from GOM and perform a mobile measurement there.